Industrial noise sensors are devices that detect and measure noise levels in industrial environments. They play a critical role in maintaining safe and healthy working conditions for employees and compliance with local and national noise regulations. This note will provide an overview of industrial noise sensors, including their applications, types, and operation principles.

Applications of Industrial Noise Sensors

Industrial noise sensors are used in a variety of applications to monitor and control noise levels. Some of the most common applications include:

- Factory noise monitoring: In industrial settings such as factories, noise levels can be high and can cause hearing damage to workers. Industrial noise sensors can be used to monitor the noise levels in these settings to ensure they are within safe limits.

- Construction site noise monitoring: Construction sites can generate high levels of noise that can affect the health and well-being of workers and nearby residents. Industrial noise sensors can be used to monitor and control noise levels in these settings.

- Airport noise monitoring: Airports generate high levels of noise from aircraft taking off and landing. Industrial noise sensors can be used to measure noise levels and determine the impact of airport noise on nearby communities.

- Traffic noise monitoring: Industrial noise sensors can be used to monitor traffic noise levels in urban areas and help reduce noise pollution.

Types of Industrial Noise Sensors

There are different types of industrial noise sensors, each with its own strengths and weaknesses. Some of the most common types include:

- Sound level meters: Sound level meters are portable devices that measure the sound pressure level (SPL) of noise in decibels (dB). They are used to measure noise levels in different locations and can provide real-time data on noise levels.

- Noise dosimeters: Noise dosimeters are small, wearable devices that measure noise exposure over time. They are typically used to monitor noise exposure for workers who are exposed to noise for extended periods.

- Octave band analyzers: Octave band analyzers are used to measure the frequency distribution of noise. They break down noise into frequency bands and can help identify the sources of noise.

- Environmental noise monitors: Environmental noise monitors are stationary devices that are installed in specific locations to measure noise levels over time. They are used to monitor noise levels in areas where noise can have a significant impact on the environment and human health.

Operation Principles of Industrial Noise Sensors

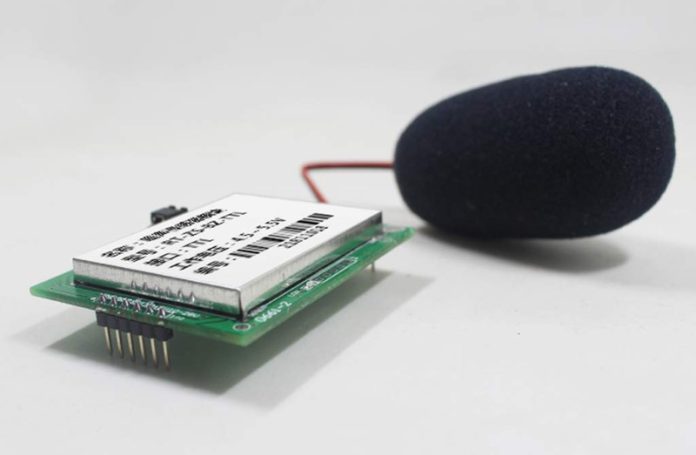

Industrial noise sensors operate on the principle of sound detection. Sound waves are detected by a microphone or other sensing element and converted into an electrical signal. This signal is then processed by the sensor to provide information about the noise level and other characteristics of the sound.

The most common parameter used to measure noise levels is the sound pressure level (SPL). SPL is measured in decibels (dB) and represents the logarithmic ratio of the measured sound pressure to a reference sound pressure. The reference sound pressure is typically the threshold of human hearing, which is around 20 µPa (microPascals).

In addition to measuring noise levels, industrial noise sensors can also provide information about the frequency distribution of noise. This information can be used to identify the sources of noise and determine the best methods for reducing noise levels.

Conclusion

Industrial noise sensors play a critical role in ensuring safe and healthy working conditions for employees and compliance with local and national noise regulations. There are different types of industrial noise sensors, each with its own strengths and weaknesses, and they operate on the principle of sound detection. By providing real-time data on noise levels and other characteristics of sound, industrial noise sensors help to identify sources of noise and determine the best methods for reducing noise levels.